Repair and Reconditioning

Repair and Reconditioning is an essential service to keep the equipment healthy and in good operation. Various components get worn-out / damaged during operation which have to be rectified and reused.

We have a proven record in carrying out repairs and refurbishment with the aid of modern techniques and equipment.

We offer total Repair and Reconditioning assistance for

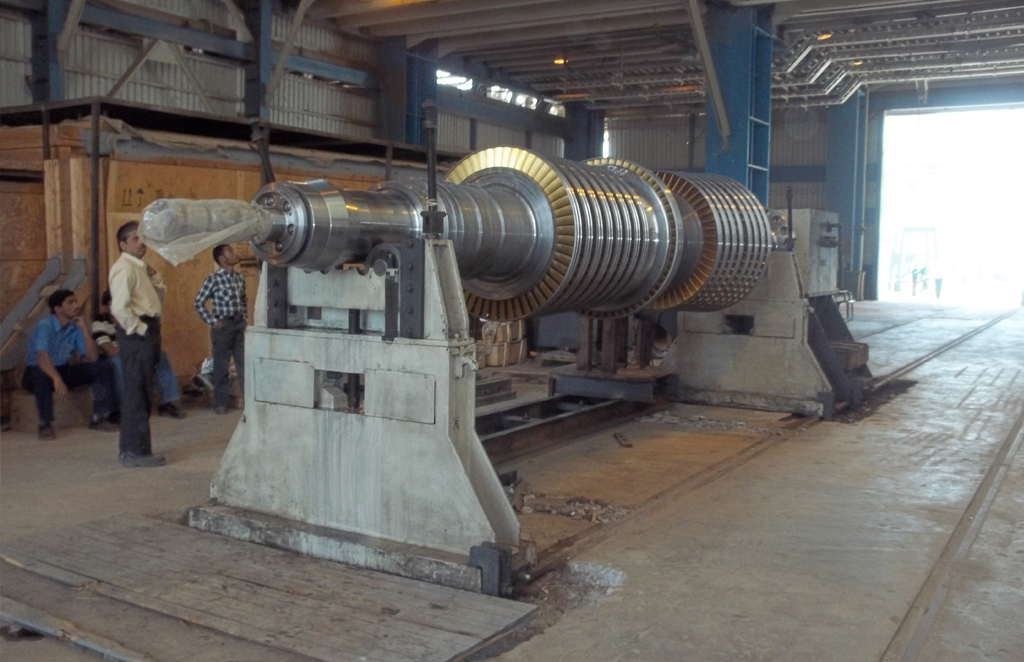

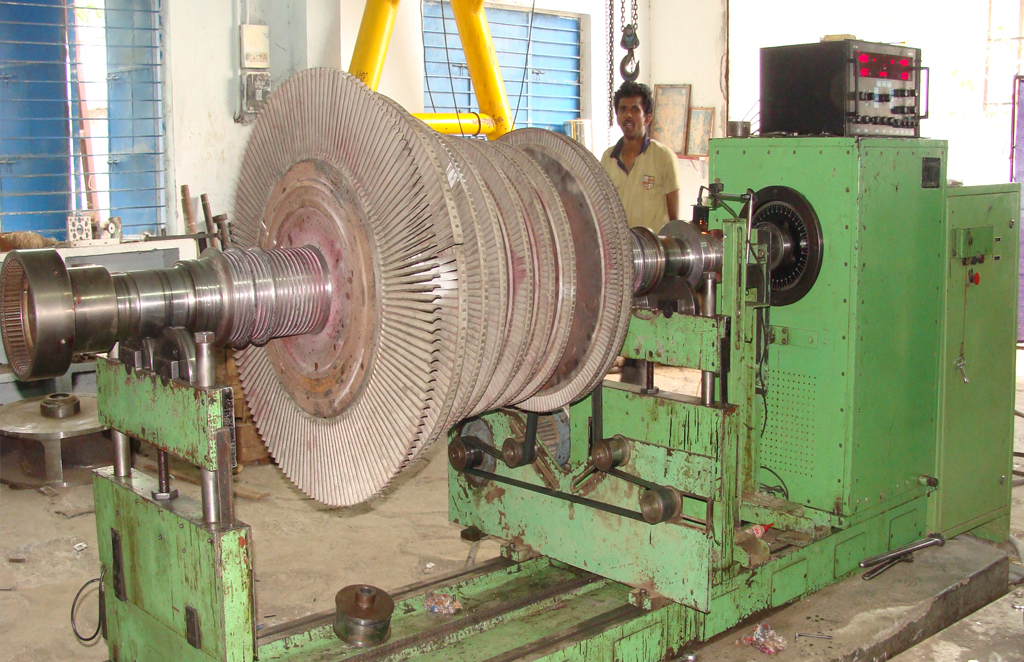

Steam Turbines

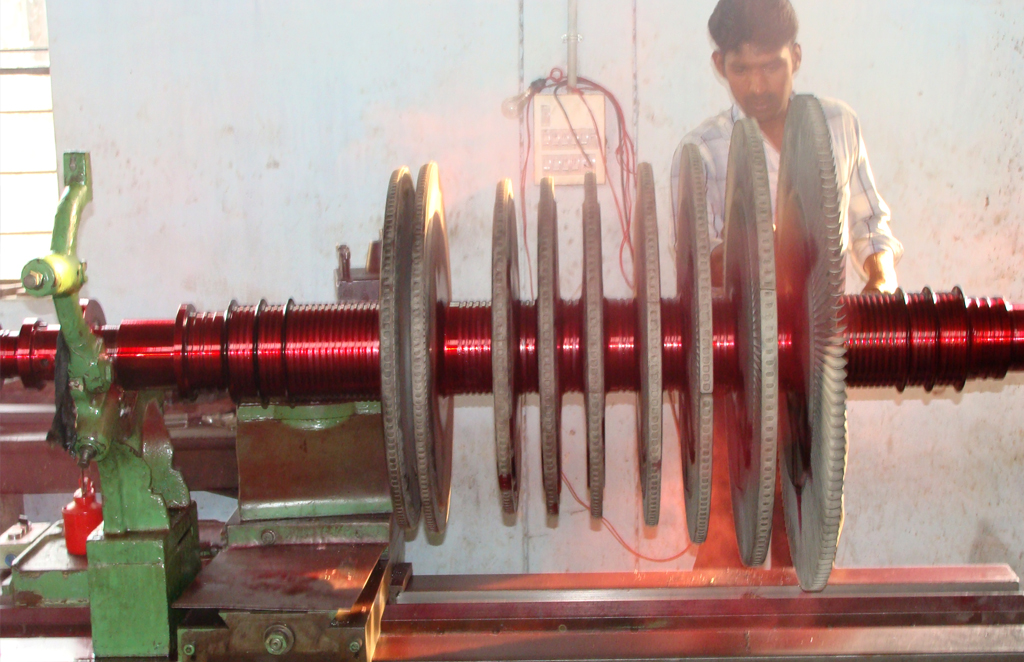

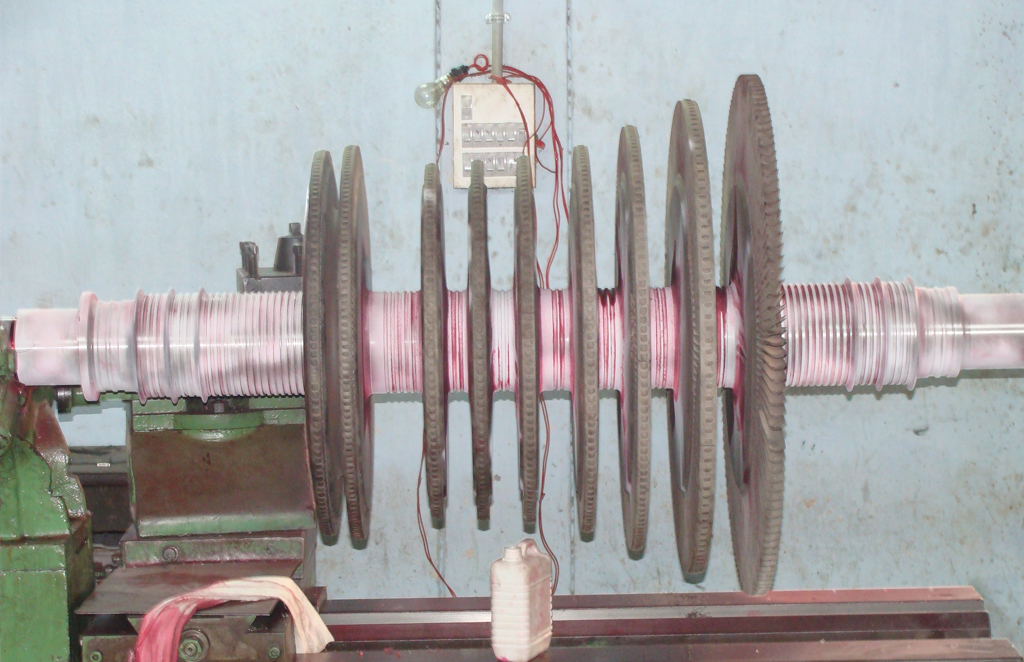

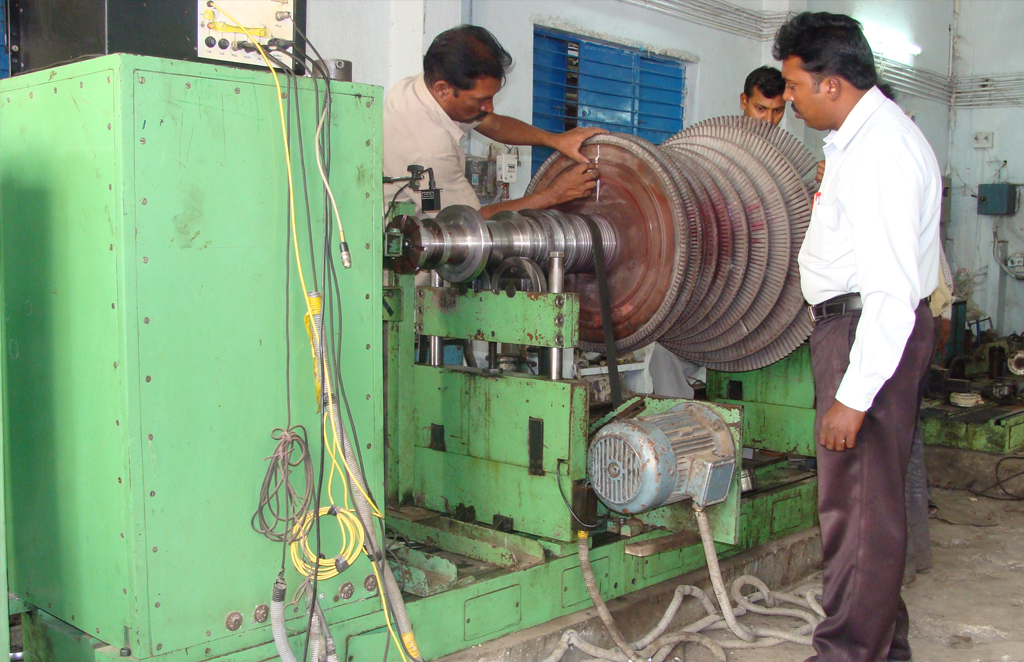

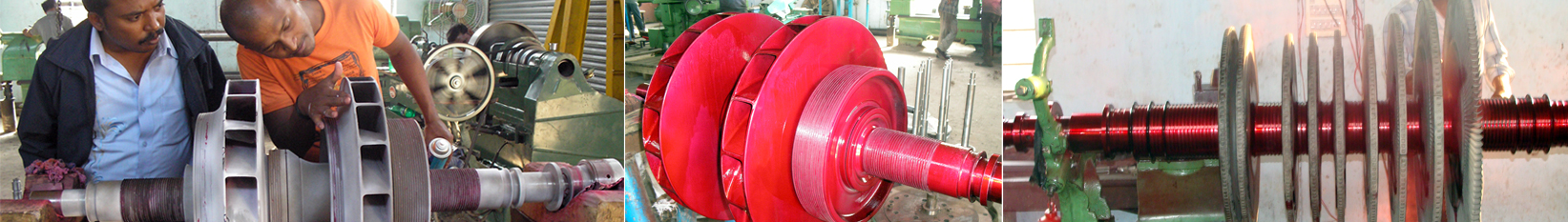

- Repair & Reconditioning of Turbine Rotors followed by thorough cleaning, NDT and Low (or) Rated Speed balancing in vacuum Tunnel as per International Standards.

- Re-blading, Refinning of Turbine Rotors, Guide Blade Carriers etc.,

- Rebabbiting of Journal Bearings.

- Re-finning of Steam Glands, Oil Glands.

- NDT & RLA Studies.

Generators

- Various types of electrical tests to be conducted to check the healthiness of Generator Rotor and Stator.

- Replacement of Slip Rings.

- Balancing of Generator Rotors.

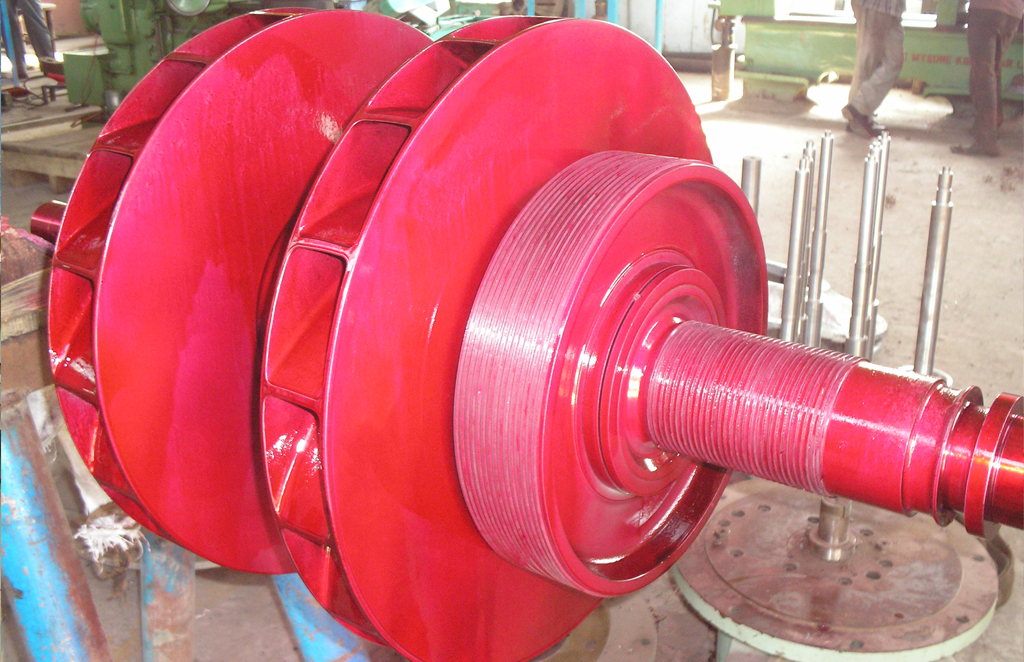

Centrifugal Compressors, Blowers and Pumps

- Repair and Reconditioning of Rotors and Diaphragms.

- Replacement of Oil Seal Bushes, Gas Seal Bushes, Impellers on the Compressor Rotor and High Speed Balancing of Compressor Rotors at its rated speed.

- NDT and RLA Studies.

Heat Exchangers

- High Pressure Water Jet Cleaning of Heat Exchanger Tubes.

- Removal and re-tubing including hydro test.